PVC vs. PTFE Welding: Which Technology is Better for Your Project?

Welding plastics is a key technology in various industrial sectors. Choosing the right welding method significantly impacts the durability and efficiency of the final products. The two most commonly used materials in welding processes are PVC (polyvinyl chloride) and PTFE (polytetrafluoroethylene). Each material has specific properties that may perform better or worse depending on the project. This article provides a detailed comparison of PVC and PTFE welding, discussing their applications, advantages, disadvantages, and when to choose each technology.

What is PVC Welding?

PVC welding is the process of joining polyvinyl chloride using heat and pressure. PVC is a popular material in the industry due to its durability and chemical resistance. Common welding technologies for PVC include high-frequency (HF) welding, impulse welding, and hot plate welding. These methods achieve durable and airtight connections.

Applications: PVC is used in industries such as film production, packaging, furniture, and sealing in construction. It is also utilized in the chemical industry due to its high resistance to various substances.

Advantages of PVC Welding

- Chemical Resistance: PVC is highly resistant to acids, bases, and salts, making it ideal for chemical industry applications.

- Ease of Molding: The material is relatively easy to shape and mold, allowing for quick and efficient welding processes.

- Durability: Welded PVC provides long-lasting and strong connections that retain their mechanical properties even under harsh conditions.

- Cost-Effectiveness: PVC is a cheaper material compared to other plastics, positively impacting overall production costs.

Disadvantages of PVC Welding

- Welding Temperature: The PVC welding process requires precise temperature control. Excessively high temperatures can degrade the material, reducing weld quality.

- UV Sensitivity: PVC is not resistant to prolonged exposure to sunlight, which can lead to yellowing and brittleness.

- Limited Flexibility: Welded PVC may be less flexible compared to other materials, which can be problematic in certain applications.

What is PTFE Welding?

PTFE welding involves joining polytetrafluoroethylene using heat and pressure. PTFE is known for its chemical resistance and high melting point, making it an ideal choice for many specialized applications. However, due to its properties, PTFE welding is technically more demanding compared to PVC.

Applications: PTFE is commonly used in the aerospace, medical, chemical, and energy industries, especially where high resistance to temperature and chemical exposure is required.

Advantages of PTFE Welding

- High Chemical Resistance: PTFE is nearly completely resistant to most chemicals, making it ideal for chemical industry applications.

- High-Temperature Resistance: PTFE is one of the most heat-resistant materials, making it suitable for applications with extreme temperature requirements.

- Low Adhesion: This material has very low adhesion properties, making it easy to clean and applicable in processes that require minimal friction.

Disadvantages of PTFE Welding

- Complexity: PTFE welding requires specialized knowledge and precise process control, which can significantly increase production costs.

- High Material Cost: Compared to PVC, PTFE is considerably more expensive, affecting the overall project cost.

- Limited Molding Capabilities: PTFE is more challenging to mold compared to other plastics, which may limit its applications in more complex projects.

Comparison of Technologies

When comparing PVC and PTFE welding, both materials have their applications in various industrial projects. PVC welding is significantly simpler and cheaper, making it a better choice for projects that require quick and cost-effective solutions. PVC performs excellently in the packaging industry and in producing materials with moderate chemical requirements.

On the other hand, PTFE welding should be considered for projects requiring resistance to extreme temperatures and aggressive chemicals. While PTFE welding is more complex and costly, its physicochemical properties often outweigh those offered by PVC.

Summary

Choosing between PVC and PTFE welding depends on the specifics of the project. If the project requires a material with high strength, chemical, and thermal resistance, PTFE welding will be the best solution. However, if cost, ease of production, and material availability are crucial, PVC welding will be a more economical option.

If you have doubts, it’s worth consulting an expert who can help you select the appropriate welding technology for your project’s specific requirements.

Contact Us!

If you are wondering which welding technology—PVC or PTFE—will be best for your project, don’t hesitate to contact the experts at Abastran. We specialize in PVC welding and offer comprehensive advice and services tailored to your needs. Click here to learn more and schedule a consultation. Let us help you realize your project with the highest precision and quality!

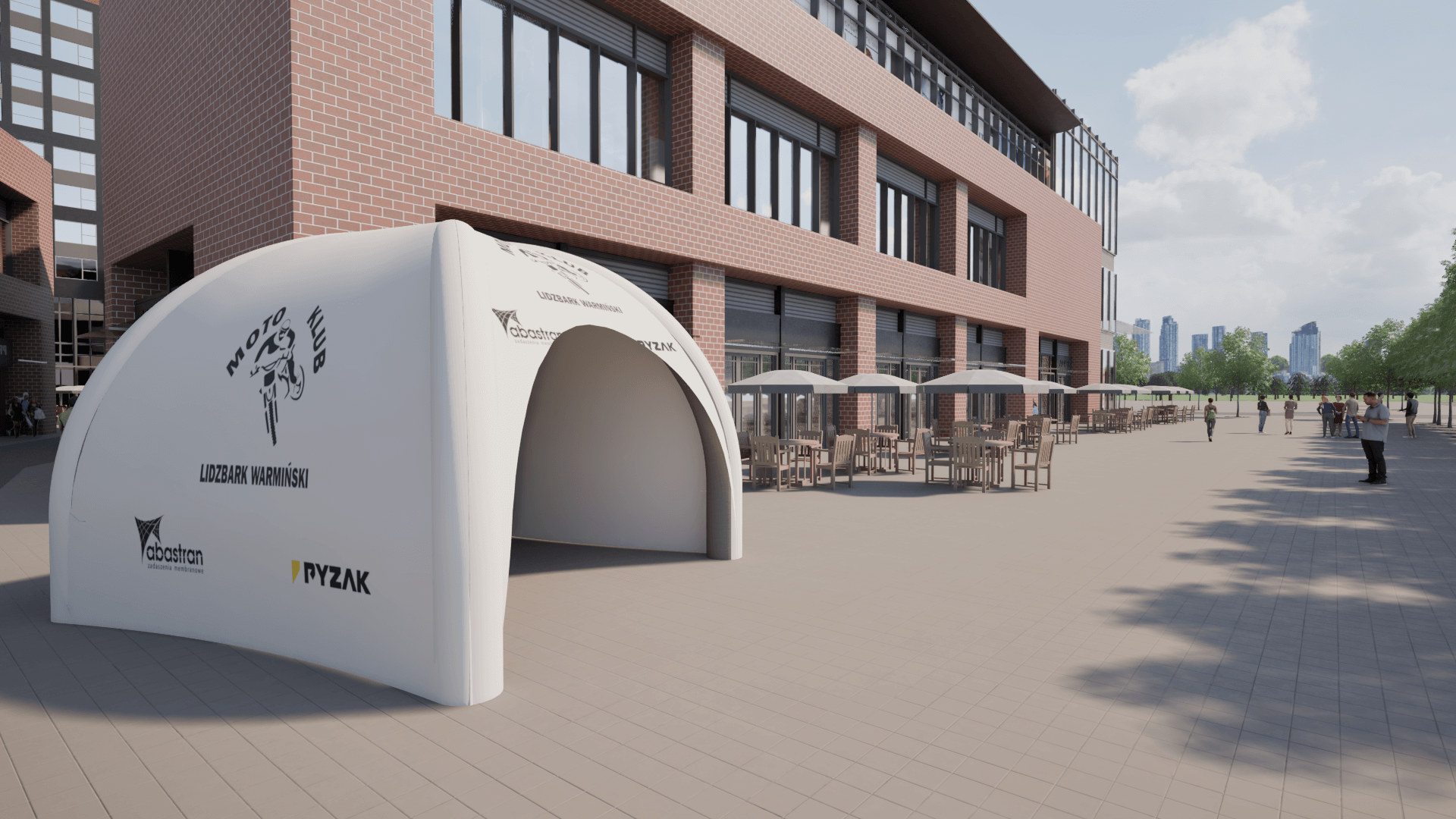

Advertising Tents as an Investment – How to Increase Brand Recognition at Events?

Competition for Innovative Membrane Roofing – Results and Inspirations

This year, we had the pleasure of organizing a competition together with the Faculty of Architecture at the Silesian University of Technology for 6th-semester students to design innovative membrane roofing. The award ceremony, held at the Faculty of Architecture in Gliwice, was the culmination of the young designers’ creative and technical journey.