Advertising Tents as an Investment – How to Increase Brand Recognition at Events?

In the buzz of conversations, a sea of competitive stands, and the overload of stimuli that accompany trade fairs, festivals, or outdoor events, getting your brand’s message across becomes a real challenge. Companies compete in ideas to attract attention, often forgetting about the foundation that can become their most effective advertising medium. This foundation is the advertising tent – a solution combining the functionality of shelter with the power of a mobile billboard.

It’s much more than just a temporary cover; it’s a strategic event marketing tool that, thanks to its mobility, huge advertising surface, and potential return on investment, can genuinely impact business results. In this article, we’ll guide you through the selection, design, and calculation process, proving that a well-planned tent is an investment that pays off at every event.

Why is an Advertising Tent an Investment, Not a Cost?

Perceiving an advertising tent solely as an operational expense is a fundamental error. In reality, it’s a long-term marketing asset whose value depreciates with each subsequent event. Unlike ephemeral digital campaigns or one-off press ads, a professional pop-up tent serves the company for many seasons, consistently building its visibility.

The return on investment (ROI) here becomes measurable not only through direct sales at the stand but also through increased brand recognition, which translates into future customer purchasing decisions. One tent can be used at trade fairs, family picnics, local sports competitions, and as a promotional point in front of the company headquarters, working for the brand image every time.

When analyzing profitability, it’s worth looking at metrics known from other advertising channels, such as CPM (Cost-Per-Mile), which is the cost of reaching a thousand recipients. The cost of purchasing a tent, spread over a dozen or several dozen events over a few years, often turns out to be significantly lower than the sum of expenses for comparable outdoor advertising formats.

Experts estimate that the break-even point for purchasing a tent is reached after participating in just 4-5 events annually compared to the costs of regular rental. Of course, storage costs should be included in the full picture, but for companies actively operating in the field, having their own, always-ready-to-use medium is an invaluable logistical and financial advantage.

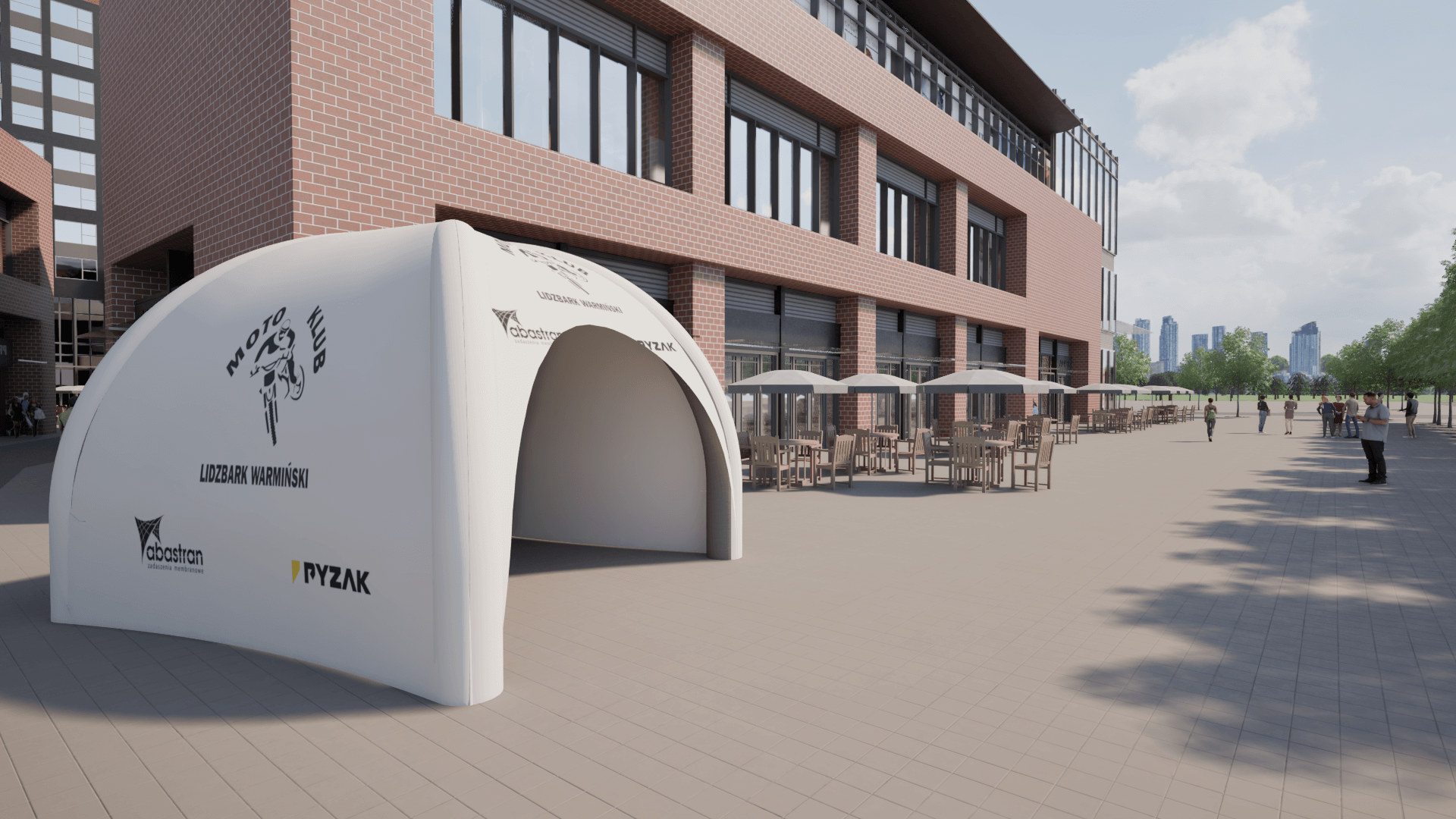

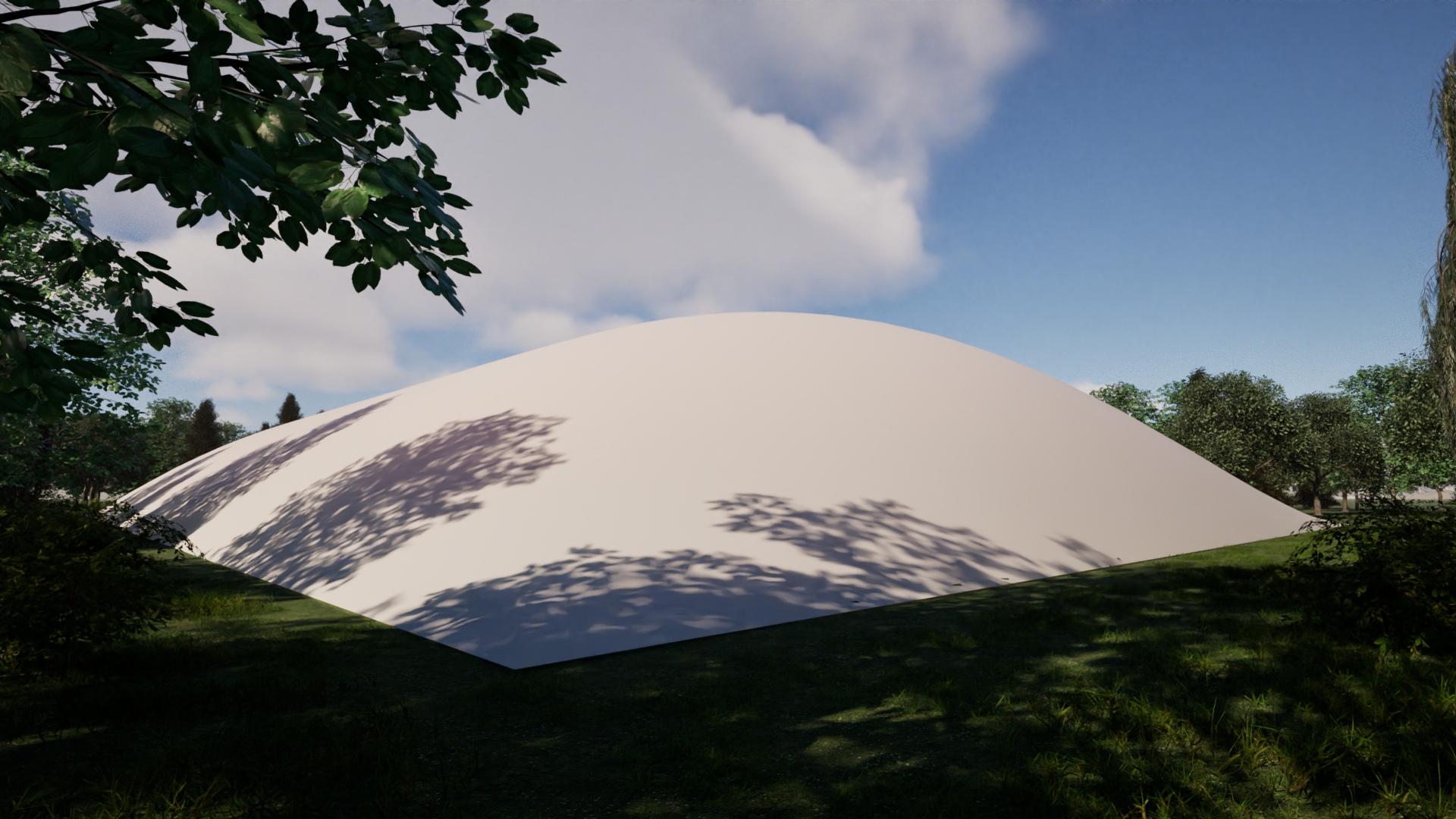

How a Tent Increases Brand Recognition at the Event Location

In a crowded trade fair or festival area, where most stands blend into a uniform mass, a tall, colourful tent becomes a visual landmark. Its roof, rising above the heads of the crowd, is visible from afar and acts like a magnet for the eyes of potential customers. It is the first thing that communicates your brand’s presence, even before visitors have a chance to read any brochure. A professionally made tent with striking graphics builds an immediate impression of solidity and attention to detail, which subconsciously transfers to the perception of the entire company and its offer. It is an investment in the first impression, which cannot be made twice.

The power of the tent lies in its huge advertising surface, which can be fully utilized. A standard 3×3 meter model offers nearly 35 m² of printable space, including the roof and walls. This allows for creating XXL format branding that is impossible to ignore. The key strategy here is to use the 360-degree effect. Placing the logo not only on the front valance but on every wall and the peak of the roof ensures the brand is perfectly visible from every direction, regardless of where attendees are approaching from. Such comprehensive exposure maximizes memorability and solidifies the company’s image in the minds of the audience.

Choosing the Right Model for Specific Goals

The most popular and versatile solution on the market are advertising tents, based on a scissor structure. Their main advantage is lightning-fast assembly and disassembly, which takes a skilled team literally 60 seconds, invaluable during dynamic promotional campaigns or one-day events. The lightweight yet durable aluminum frame facilitates transport and carrying, making such a tent an ideal tool for mobile sales and marketing teams that frequently change locations.

The decision about the tent size should be dictated by both the specifics of the events and the planned way it will be used. The most versatile 3×3 meter model will work well as a standard trade fair stand, information point, or tasting station. It provides enough space for 2-3 staff members and basic equipment such as a counter or roll-up. If there’s a need to create a larger zone, for example, a chillout area, VIP customer service point, or a mini-stage, it’s worth considering larger sizes like 4.5×3 m, 6×3 m, or using modular systems that allow connecting several tents into one cohesive space.

A key parameter, especially for outdoor events, is the resistance of the tent structure to weather conditions. Professional advertising tents have reinforced aluminum profiles and covering made of durable, waterproof polyester fabric. Attention should be paid to the wind resistance declared by the manufacturer, which for solid models, when properly anchored using stakes or weights, can reach up to 50 km/h. This durability guarantees the safety of both staff and guests and protects valuable promotional materials and equipment from damage.

Designing Graphics That Truly Work

The secret to effective graphic design on a tent is the ‘less is more’ principle. Its main task is to attract attention from a distance and quickly identify the brand, so resist the temptation to put too much information on it. The central point of the design should be a clear, large logo and a concise, catchy slogan (claim) that communicates the company’s key value in a few words.

Full contact details, a long list of services, or blocks of text are unreadable from a distance and, instead of attracting, create visual chaos.

For the design to be effective, it must consider the viewer’s perspective. Key graphic elements, such as the logo or main message, should be placed in the eye-level zone, i.e., at a height between 1.2 and 1.6 meters on the tent walls. High color contrast between the background and graphics is also extremely important to ensure readability even in bright sun. A good practice is to test the design in grayscale – if the logo and text remain readable, it means the contrast is appropriate. It’s also worth considering placing a subtle Call to Action, for example, an arrow with the text ‘Welcome inside’, near the entrance to directly guide visitor traffic.

Buying or Renting – Cost Analysis and Usage Scenarios

The decision between buying and renting an advertising tent is a strategic choice dependent on two main factors: the frequency of participation in events and the need for full personalization. Renting is an extremely attractive solution for companies that participate in events sporadically, for example, once or twice a year. This eliminates the need for a high initial cost and also frees up the obligation of storing and maintaining the equipment. It’s a flexible and low-cost option for starting out or for the needs of a one-off, non-standard project.

On the other hand, buying a tent becomes significantly more cost-effective for companies for whom event marketing is a permanent element of their strategy. As mentioned earlier, the break-even point for purchase versus rental is usually around 4-5 events per year. Owning your own tent provides full freedom and 24/7 availability – you don’t have to worry about booking dates or equipment availability during the busy trade fair season. Above all, ownership gives unlimited personalization possibilities. Every centimeter of the roof and walls can be designed according to the brand’s visual identity guidelines, creating a unique and consistent image that cannot be achieved by renting standard, generic models.

Analyzing costs in the long term, purchasing should be treated as an investment in a durable marketing asset. Although the initial outlay is higher, it is spread over many years of use. However, it’s worth remembering additional costs, such as print renovation every 3-4 years to maintain its freshness and color intensity, and potential storage costs. Nevertheless, for a company active in the market, the sum of these expenses will still be lower than regular rental fees, and the benefits of having a fully personalized, always-ready-to-go marketing tool are priceless.