How to Choose the Right Roofing Structure for Sports Facilities?

Are you facing the decision of choosing a roofing system for your sports facility? This is one of the most crucial choices you will make. A well-selected roof is much more than just protection from rain or sun. It’s a guarantee that your facility will be functional, safe, and comfortable for users for many years to come. Today’s market offers a wealth of possibilities, from traditional, robust steel structures and aesthetic glued laminated timber to ultra-modern, lightweight membrane roofing systems and practical inflatable halls. Each of these solutions has its specific advantages, but also certain limitations.

What Types of Roofing Structures Can You Choose From?

Before making a decision, it’s worth understanding the basic types of roofing structures used in sports facilities. They differ in material, construction technology, appearance, and, of course, price. Understanding these differences is the first step towards choosing the solution perfectly tailored to your needs.

We have classic structures that have proven their worth over the years: steel, aluminum, and timber. Each offers strength and durability. Alongside them, increasingly popular innovative lightweight roofing systems are emerging, such as membranes and inflatable halls. These open up entirely new possibilities in terms of shape, construction speed, and energy savings. Let’s not forget about tent halls or prefabricated elements, which work excellently as temporary solutions or when quick assembly is essential.

Solid Foundation: Steel, Aluminum, and Timber Structures

Steel structures are a common choice for large facilities, such as stadiums or arenas. Their strength lies in exceptional durability. They allow roofing vast areas without a dense network of columns, providing great freedom in interior arrangement. Steel also gives architects room to maneuver, enabling the creation of both simple and highly imaginative roof shapes. However, you must remember that steel requires protection against corrosion, and its weight imposes specific requirements on foundations.

A lighter alternative is aluminum. Its main advantage is natural resistance to rust, eliminating the need for additional protection and reducing maintenance costs. The lower weight of aluminum profiles facilitates and speeds up assembly. It’s a good choice, especially where moisture is present, such as in swimming pools or ice rinks. However, aluminum may have some limitations when it comes to achieving extremely large spans, and the material itself can be more expensive than steel.

Glued laminated timber brings a unique atmosphere, aesthetics, and warmth to sports facilities. It is valued for its natural appearance, good acoustic properties, and ecological character. Glued laminated timber structures allow the creation of impressive arches and frames, ideal for sports halls, riding arenas, or courts. However, remember that timber requires adequate protection against moisture and fire, and its capabilities for very large spans are less than those of steel.

Modern Lightness: Membrane and Inflatable Structures

Membrane roofing systems are a true revolution in architecture. They utilize special, durable fabrics (PVC or PTFE) stretched over a lightweight supporting structure. Their biggest advantage? Exceptional lightness and the ability to create almost any fluid shape. Membranes transmit natural daylight excellently, which helps save on artificial lighting, and special coatings make them durable and self-cleaning. This is an ideal solution for stadiums, amphitheaters, or courts, giving facilities a modern look. However, remember that the design and installation of such structures require specialized knowledge – at Abastran, we have been specializing in creating even the most complex membrane and ETFE roofing systems for years.

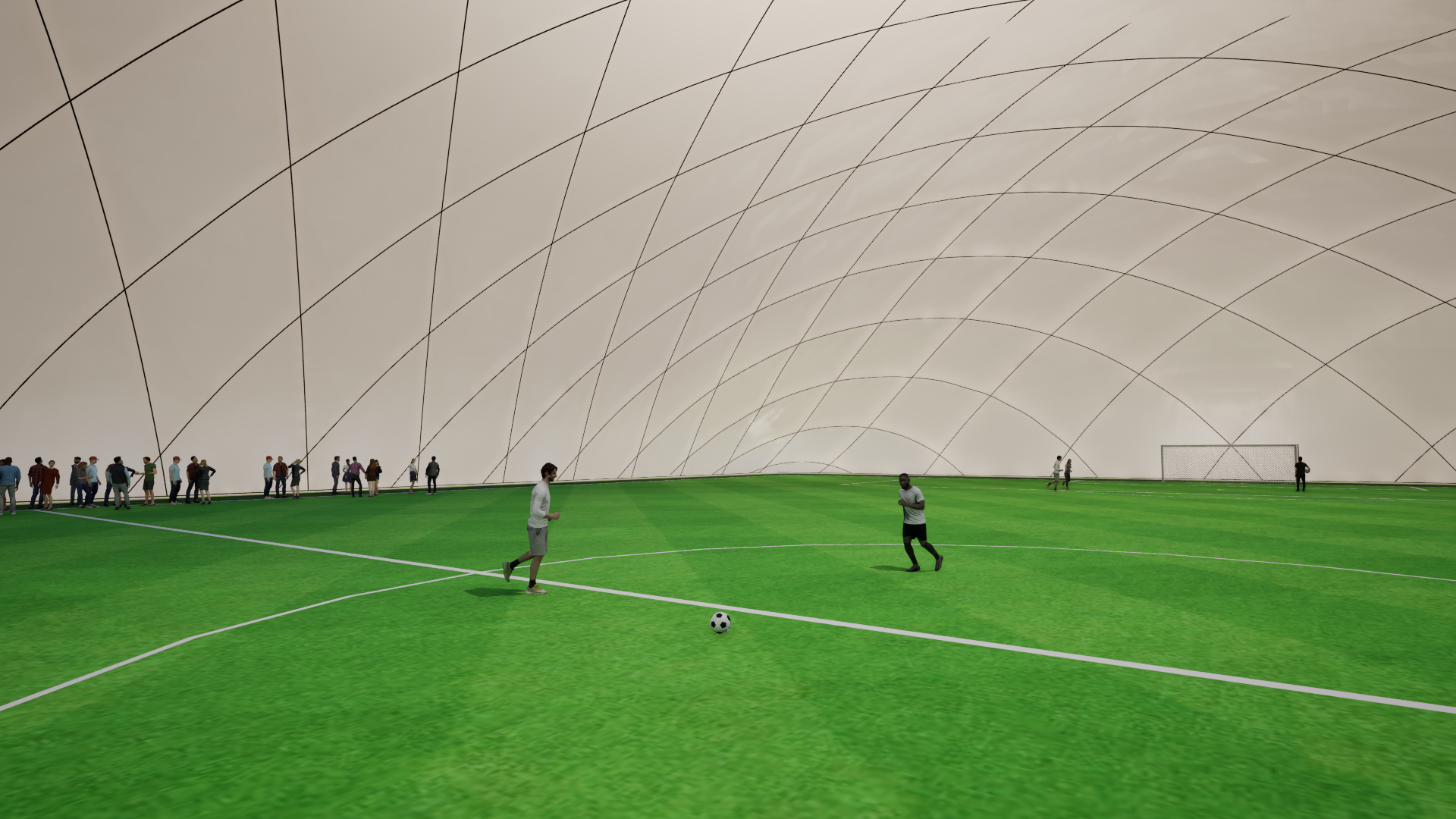

Inflatable halls, often called “domes” or “bubbles,” operate on a different principle. Here, the envelope is held up by internal air pressure. This solution is very cost-effective and incredibly fast to assemble. It works perfectly for covering fields, courts, or ice rinks seasonally or year-round. The main advantage is the possibility of quick setup and equally quick dismantling. However, you must account for the energy costs required to maintain the internal pressure and certain limitations in user comfort, especially in strong winds.

Flexible Solutions: Tent and Prefabricated Structures

Tent halls, typically based on a steel or aluminum frame covered with PVC fabric, are an excellent option for temporary or seasonal facilities. They are suitable as roofing for training pitches, warehouses, or event spaces. Their main advantages are speed of assembly and disassembly, relatively low cost, and ease of expansion. Modern tent halls can be used year-round, but their durability is generally less than that of permanent structures.

Prefabrication is a method involving the production of ready-made structural elements (e.g., concrete, steel) in a factory and assembling them on the construction site. This significantly shortens the investment time and ensures high, repeatable quality. Prefabricated elements are used in the construction of the roof, as well as stands or walls. This solution is particularly beneficial for standard hall designs. However, it may limit individuality and the freedom to shape unusual architectural forms.

Key Criteria for Choosing a Roofing Structure

Choosing a specific roofing technology is not an easy task. There is no single ideal solution for everyone. To make the best decision for your facility, you must carefully analyze several key factors. What is most important to you? What are the specific needs of your investment?

Consider the intended use of the facility, the available budget, and the time you have for implementation. Take into account local weather and ground conditions. Don’t forget about building regulations, safety standards, and any guidelines from sports federations. Only a comprehensive view of these aspects will allow you to choose a structure that will be a perfect fit: safe, durable, and economical.

What will the facility be used for?

The basic question is: what function will your sports facility serve? A football stadium roof has different requirements than a basketball hall, and still different ones than a swimming pool or court cover. Size, required height, access to light (natural or artificial?), acoustics, the need for integration with ventilation – all of this influences the choice of material and technology. For example:

- Large stadiums: often require large spans without supports, favoring steel or membrane structures.

- Swimming pools: resistance to moisture and corrosion is crucial, making aluminum or specially treated timber a good choice here.

- Team sports halls: good acoustics and appropriate height may be important, which can be achieved using glued laminated timber or steel.

Also, remember the specifics of the particular sport discipline. Some require very stable conditions, others special lighting. If you plan a multi-functional facility, the roof structure must be versatile enough to meet various needs, for example, by allowing the suspension of heavy equipment.

What is your budget and schedule?

Costs and implementation time are often decisive factors. Different technologies have different material prices, assembly costs, and required construction time. Steel or timber structures may be more expensive upfront but offer great durability. Inflatable or tent halls, on the other hand, are cheaper and faster to build, which is a significant advantage when you have a limited budget or need to open the facility quickly.

However, remember that costs are not just about construction. Expenses for subsequent operation are equally important: maintenance, repairs, heating, lighting. Lightweight membranes can lower electricity bills by utilizing daylight. Good insulating materials, like timber, will reduce heating costs. Looking long-term, a more expensive solution initially may prove more cost-effective over years of use.

Where will the facility be built, and what are the weather conditions there?

The location of your investment is of great importance. You must consider the local climate, especially snow and wind loads. In areas with heavy snowfall, the roof must be strong enough to bear its weight. Where strong winds blow, structural stability is crucial. These factors can influence the choice of material (e.g., strong steel) or roof shape (e.g., aerodynamic membrane forms).

Don’t forget about ground conditions. Heavy structures require solid foundations, which can significantly increase investment costs on weak ground. In such situations, lightweight aluminum, membrane, or inflatable structures may be a better choice. Also, pay attention to the surroundings – proximity to other buildings or trees can affect wind load.

What are the regulations and safety standards?

Every sports facility must meet specific legal requirements. The roof design must comply with standards regarding loads (snow, wind), fire safety, and overall structural safety. Regardless of the chosen technology, the design must be carried out by authorized engineers, and the entire construction properly supervised and documented.

If you plan to host official competitions, you must also meet the requirements of specific sports federations (e.g., FIFA, FIVB). These may concern field dimensions, hall height, lighting, or even colors. Check these guidelines at the outset to avoid problems with obtaining facility approval in the future. If you are facing the challenge of choosing the best solution for your facility, contact us – Abastran experts will be happy to answer your questions and help you select the optimal technology.