Designing Steel Structures for Gusset Plate Halls – What Does It Look Like?

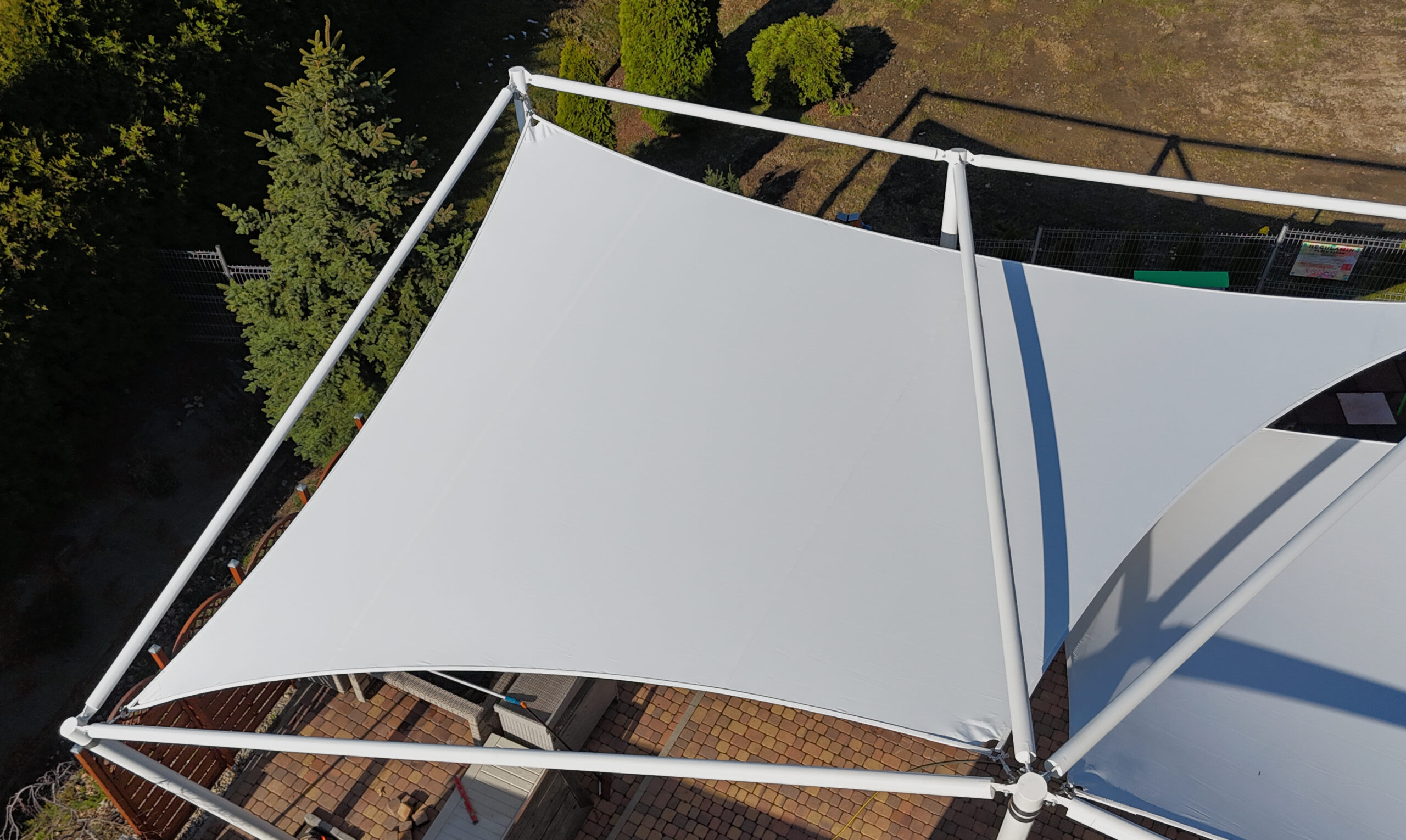

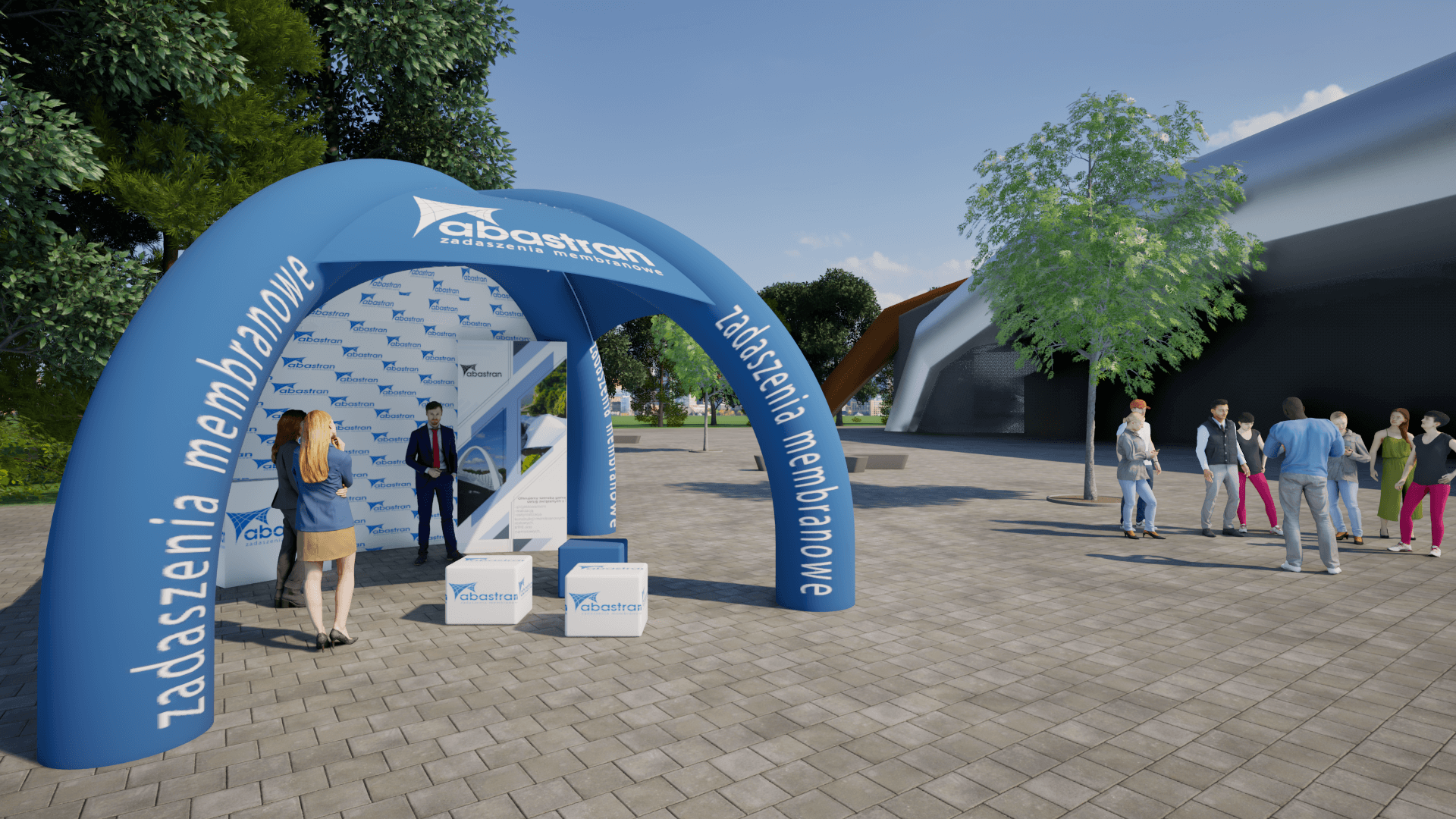

When you decide to build an industrial facility, one of the most important choices you face is the type of structure. At Abastran, we specialize in designing steel structures, which, thanks to their properties, provide unmatched strength with relatively low self-weight. A particularly interesting solution is gusset plate halls, where the main load-bearing elements are designed as individually calculated gusset plates – profiles welded from plates, which we precisely adjust to the forces occurring in your structure. Thanks to our calculations, we can optimize steel consumption by up to 25-30% compared to standard solutions, and you receive a structural design perfectly tailored to your needs. In addition to gusset plate halls, our offer also includes designs for membrane and tent structures – alternative solutions that may better suit the specific requirements of your project.

The Process of Designing Steel Structures for Gusset Plate Halls

Our work begins with creating a precise working design of the steel structure. Let’s not confuse it with the technical design you receive at the building permit stage – this only defines the general parameters and assumptions. At Abastran, we create detailed workshop documentation, which is a “recipe” for producing each element of your structure.

While working on the project, we carry out advanced structural optimization, which allows us to reduce the weight of steel by up to 30%, while maintaining all strength parameters. We use modern CAD/CAM software, thanks to which we can precisely model each element and simulate various load scenarios – from the weight of snow to the action of strong wind. This stage is crucial, because accurate planning of every detail translates into material and financial savings, and efficient assembly.

It is worth emphasizing that it is at the design stage that we make the most important decisions regarding your structure – we determine the cross-sections of elements, spacing, types of connections, and specify materials. Thanks to our experience in structural calculations, we can advise you on the best solutions that will meet your expectations both technically and economically.

Calculations and Specification of Steel Elements for the Manufacturer

Once you accept the design, we prepare detailed documentation for implementation. The first step is to develop a material specification in accordance with our calculations. In Abastran projects, we do not save on quality – we specify high-strength steel from proven suppliers, which is the foundation of your structure’s durability.

In our documentation, we specify the exact parameters for material preparation, including abrasive blasting methods, which not only removes dirt and rust, but also increases adhesion for subsequent anti-corrosion coatings. This stage is crucial for the durability of your structure – a well-prepared surface is the basis for effective anti-corrosion protection, which will ensure many years of trouble-free use.

Our designs include detailed guidelines for cutting the material to size. Depending on the thickness and type of steel, we specify different techniques – for thinner sheets, we recommend laser cutting with an accuracy of up to 0.1 mm, for thicker elements, we recommend plasma or water jet technology. Thanks to precise calculations, we are able to design all structural elements of your steel hall with the highest accuracy, which is of great importance during subsequent assembly.

The documentation we prepare also includes detailed guidelines for further processing – making mounting holes, chamfering for welds, and, where necessary, precise bending. We define all these operations in accordance with our calculations, specifying dimensional tolerances at each stage of production. It is this precision in design that makes the elements of your structure fit together perfectly during assembly.

Designing Welding and Gusset Plate Processing Technology

The heart of the gusset plate design is welding technology. At Abastran, we design advanced welding methods, including specifying submerged arc welding (SAW) parameters, which ensures deep penetration and exceptional weld quality. Our welding specifications allow us to create connections with the highest strength, which is crucial for large structural elements such as columns or beams.

By choosing a gusset plate hall designed by us, you gain a significant advantage over solutions using standard commercial elements. We design gusset plates taking into account the actual distribution of forces in your structure. This means that where the loads are greater, we design thicker plates or higher cross-sections, and where they are smaller – we can reduce the amount of material. Thanks to this, your structure will be both durable and economical.

Every stage of the project in our company is subject to rigorous control in accordance with the PN-EN 1090 standard, which allows us to mark the finished elements with the CE mark. Our designs take into account all requirements for the qualification of contractors, including welders with appropriate qualifications. We also specify requirements for weld testing, both visual and, when required by standards, non-destructive testing (NDT). We leave no room for chance – your structure designed by Abastran must be not only functional, but above all safe.

In our designs, we also define requirements for finishing. We specify methods for removing weld spatter, cleaning the surface, and preparing for anti-corrosion protection. Depending on your requirements and the environment in which the structure will operate, we design an appropriate painting system or hot-dip galvanizing. Properly designed anti-corrosion protection is an investment in the durability of your hall, which can serve for decades.

Designing the Assembly of Steel Structures on the Construction Site

The final stage of our project is the development of the technology for assembling the structure on the construction site. At Abastran, we specify two main methods, which we select depending on the specifics of your project. For smaller objects, we design the assembly of individual elements directly on the construction site. For larger structures, we recommend block assembly, where larger assemblies are prepared on the ground and lifted as a whole, which significantly speeds up work and increases safety.

In our assembly documentation, we describe in detail the process starting with setting the main columns on the prepared foundations. Precise anchoring is the basis for the stability of the entire structure – we design assembly templates and specify requirements for measuring equipment to ensure perfect alignment of the load-bearing elements. Then we define the order of assembly of the roof beams and the method of their connection to the columns using the bolted connections designed by us.

In the following stages, we specify the installation of wall and roof bracings, which ensure the spatial stiffness of the entire hall. They ensure that the structure designed by us will be resistant to horizontal forces, such as wind or seismic loads. We also specify the method of assembling roof purlins and wall girts, which support the cladding.

Experience has taught us that precise design of elements directly translates into the speed and efficiency of assembly. When all elements fit together perfectly according to our design, the need for time-consuming adjustments on the construction site is eliminated, which significantly shortens the implementation time and reduces costs. After completing the assembly of the steel structure, you can proceed to install the roof and wall cladding, and you can enjoy the new, functional space.

Summary

Designing steel structures for gusset plate halls is a complex process, which we at Abastran carry out with the utmost care at every stage. From precise calculations and workshop design, through detailed specification of elements using high-strength steel, to professional assembly documentation – every step is crucial for the quality of the final result.

By choosing our company, you gain a partner with many years of experience in design and access to the latest calculation technologies. Our steel structure designs are not only the fulfillment of technical requirements and standards, but above all a solution tailored to your individual needs. We care about cost optimization, but never at the expense of quality.

If you are considering building an industrial hall, warehouse, or other facility requiring a solid structure, please contact us. Our specialists will help you choose the optimal design solution, including membrane structures, which are an innovative alternative to traditional solutions. Together we will design a space that will serve you for years.