Pneumatic Hall vs Traditional Tent Hall – When to Choose Which Option?

You’re facing a challenge: you need to quickly and effectively cover a sports field, expand storage space, or create a temporary production facility. You know that traditional brick construction is a long and complex process. Your attention is drawn to two lightweight construction technologies: inflatable halls and tent halls. Both offer speed of assembly and flexibility, but their DNA is completely different. This isn’t just a choice between a “balloon” and a “tent.” It’s a strategic engineering decision that will impact the functionality, safety, and operating costs of your facility for years to come.

Choosing the right technology requires understanding how each behaves under load, what energy requirements it imposes, and how it fits within legal frameworks. This guide will help you analyze the key technical parameters of both solutions. Instead of generalities, you’ll get specific information that will allow you to make an informed decision, perfectly tailored to the specifics of your project.

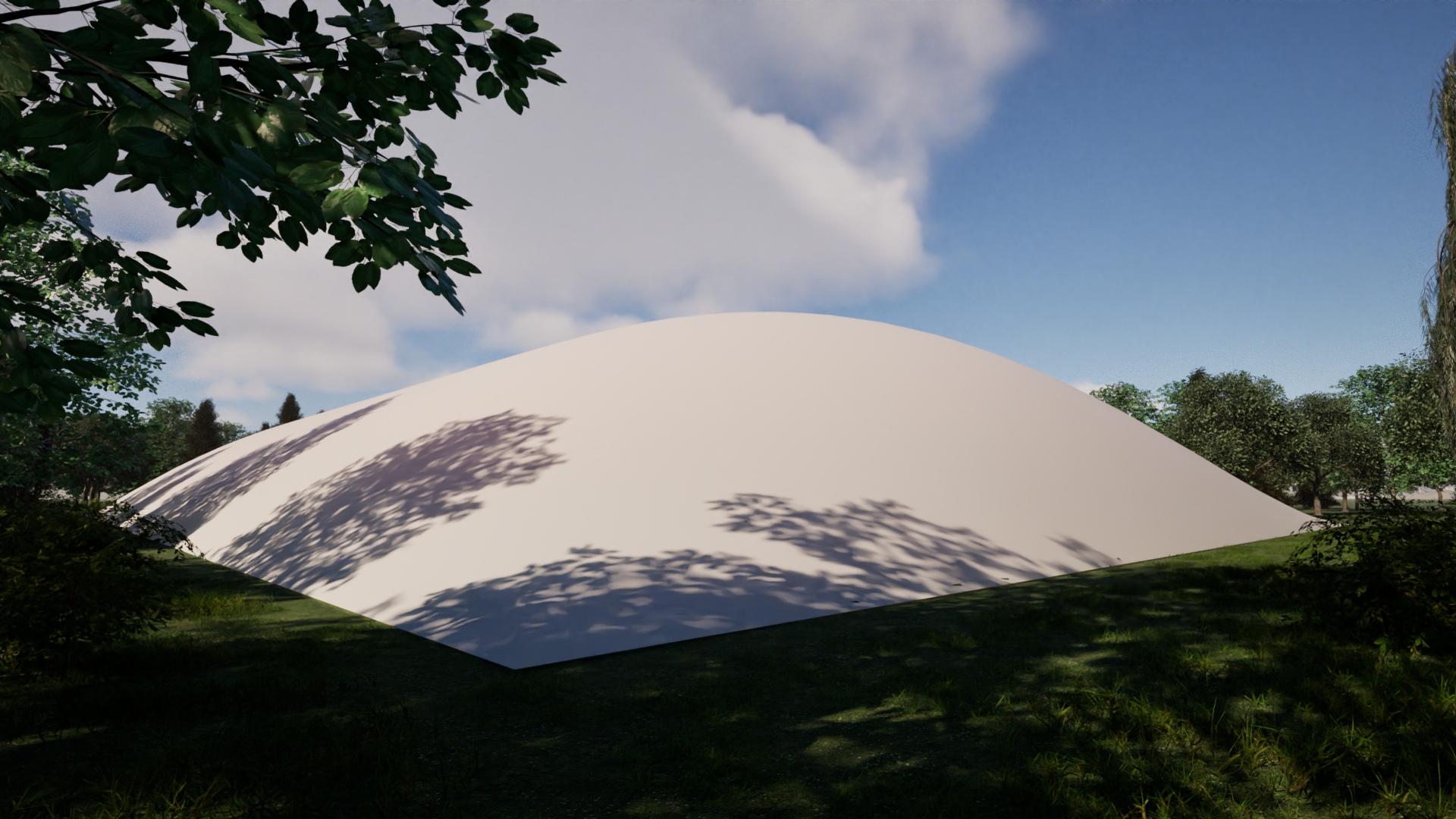

Pneumatic Structure: How Overpressure Works for You

Imagine a structure that doesn’t need a heavy steel or aluminum skeleton. Its form and stability are provided by fully controlled overpressure, maintained at a level of just 250-350 Pa (Pascals). This is the principle behind the operation of a pneumatic hall. Its support is provided by an integrated blower system that operates continuously, ensuring the structural integrity regardless of external conditions. The absence of internal columns or trusses is a fundamental advantage, giving you a completely open, unrestricted usable space.

Key to its functionality is the membrane, specifically a system of two membranes made from advanced technical PVC material (often Type III or IV). An insulating air cushion is created between them, serving two crucial functions. Firstly, it drastically reduces heat loss by eliminating thermal bridges. Secondly, it effectively prevents water vapor condensation on the inner surface of the roof, which is a common problem in many sports facilities. The entire system must be supported by reliable backup systems: a UPS power supply and a generator set, which immediately take over the operation of the blowers in case of power failure, ensuring complete structural safety.

Traditional Tent Hall: Skeleton Solidity and Modular Flexibility

In the case of a traditional tent hall, the entire responsibility for transferring loads falls to the skeleton. It is made from system aluminum profiles or, for larger spans and requirements, from hot-dip galvanized steel structures. Tent Hall Covers are stretched over this frame, most often made from a single, durable PVC tarpaulin. This modular construction is a huge design advantage – it allows for precise adaptation of the facility to the plot shape and its future, hassle-free expansion.

Unlike pneumatic halls, skeletal structures do not require constant power supply to maintain their form, which translates into a different energy consumption profile. However, their design and operation present other challenges. The flat or gable roof must be precisely calculated for snow and wind loads for a given climatic zone, in accordance with standard PN-EN 1991. In practice, this means the necessity of monitoring snow cover thickness and removing it to prevent structural overload. From our experience at Abastran, the key here is not only solid execution but also the facility manager’s awareness of their operational duties.

Key Technical Differences: What You Need to Consider

Before making a decision, compare the fundamental differences in the operation of both systems. These will determine which technology better meets your operational and design needs.

- Load-Bearing Mechanism: In a pneumatic hall, overpressure is the structural element. In a tent hall – a physical skeleton (aluminum or steel). This directly translates to the type of foundations, assembly speed, and internal adaptability.

- Thermal Insulation: A pneumatic hall with a double membrane offers integrated, high insulation thanks to the air cushion. In a tent hall, the standard is a single tarpaulin with low insulation. To achieve comparable thermal comfort, you must invest in sandwich panel walls and roof, which changes the character and budget of the entire project.

- Reaction to Snow Load: This is one of the most significant differences! The aerodynamic shape of a pneumatic hall actively prevents snow accumulation, as it simply slides off the membrane. A tent hall passively transfers snow loads to the skeleton, requiring regular inspection and intervention from your side.

- Energy Requirements: The “balloon” needs continuous power supply for the blowers. The “tent” consumes energy mainly for heating and lighting. You need to analyze which energy consumption model will be more optimal for you in the long term.

Application Scenarios: Which Technology Suits Your Needs?

The choice depends on the intended use of the facility. Each technology has areas where it excels and areas where its application would be inefficient.

Pneumatic Hall – Ideal for Sports and Year-Round Facilities

If you plan to cover tennis courts, a football field, or an ice rink, a pneumatic hall is the natural choice. Why? Primarily due to the absence of internal supports, which provides complete freedom of play. Excellent insulation and acoustics create comfortable conditions for athletes throughout the year. Furthermore, its high resistance to snow load eliminates the risk of downtime in winter and the costs associated with snow removal. This solution is designed for uninterrupted operation.

Tent Hall – Indispensable in Logistics and Industry

Do you need a storage hall or a lightweight production hall? The skeletal structure gains an advantage here. Its key benefit is the possibility of mounting cranes, suspended installations, or ventilation systems directly to the load-bearing structure. This allows for the construction of high-bay racking and adaptation of space to specific technological processes. Modularity also enables easy expansion of the warehouse in the future, which is crucial for growing companies.

Operational Efficiency and Construction Lifecycle

The initial investment cost is only part of the equation. The true efficiency of a project is revealed in the long-term perspective, considering operational costs and maintenance. In the case of a pneumatic hall, the constant cost is energy for the blowers, but you gain lower heating bills due to better insulation. In a tent hall, you don’t have this constant expense, but you must account for higher heating costs (in the tarpaulin version) and potential snow removal costs.

Equally important is material durability. Modern membrane structures made of PVC used in pneumatic halls, protected by UV-resistant layers, maintain their properties for 15-20 years. A standard tent hall tarpaulin may require replacement somewhat earlier, depending on the intensity of use and weather conditions. When planning your project, you must include these lifecycle costs in your budget.

Legal and Formal Aspects: Notification or Building Permit?

Before starting any work, you must verify two fundamental issues: the Local Development Plan (MPZP) and the provisions of the Building Law. The MPZP may specify permissible height, color scheme, or even roof type, which could favor one technology.

The Building Law allows for the construction of temporary building objects for a period of up to 180 days based on a simplified notification procedure. Both technologies fit perfectly within this possibility. However, if you plan to use the hall for longer, obtaining a building permit will be necessary. At Abastran, we always emphasize that the key to smoothly navigating the procedures is complete documentation, including a structural design with static calculations for your wind and snow zone, and non-flammability certificates for the covering (e.g., class B-s2,d0). This is not a formality; it is a guarantee of the safety of your investment and its users.

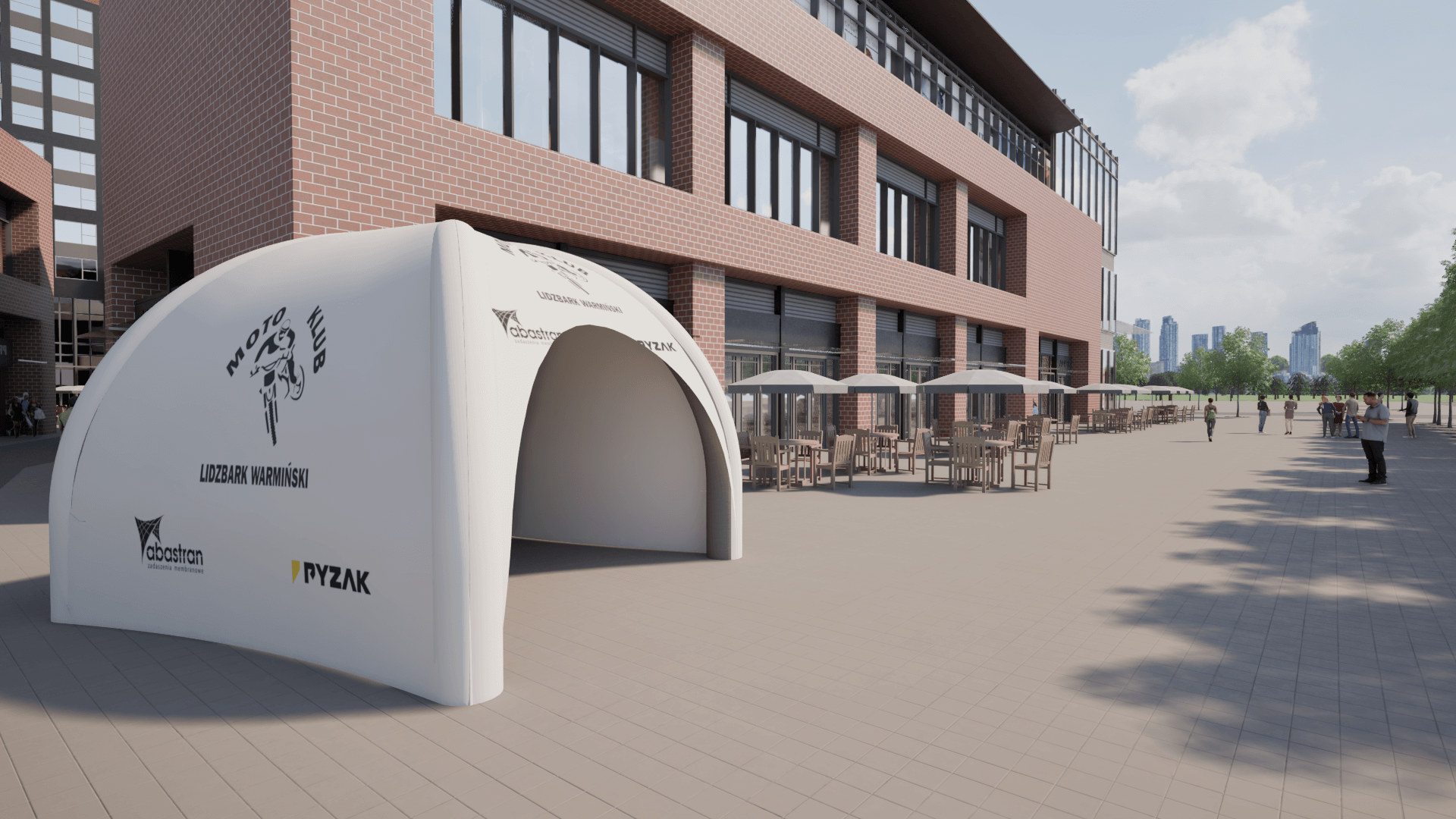

Advertising Tents as an Investment – How to Increase Brand Recognition at Events?

Competition for Innovative Membrane Roofing – Results and Inspirations

This year, we had the pleasure of organizing a competition together with the Faculty of Architecture at the Silesian University of Technology for 6th-semester students to design innovative membrane roofing. The award ceremony, held at the Faculty of Architecture in Gliwice, was the culmination of the young designers’ creative and technical journey.