How Does the Process of Designing Steel Structures Look from A to Z?

Designing steel structures is a key element of modern construction. Steel, as a construction material, has gained popularity due to its strength, durability, and design flexibility. Steel structures are used in the construction of industrial halls, bridges, office buildings, and many other structures. In this article, we will discuss the detailed process of designing steel structures—from initial assumptions to installation.

Stages of Designing a Steel Structure

Preparation and Analysis of Requirements

The first stage of design involves gathering the investor’s requirements and analyzing the location. Engineers and architects must consider both the functional and aesthetic expectations of the investor. At this stage, a site analysis is crucial, including geotechnical studies, weather conditions, and specific legal requirements. Conducting preliminary analyses allows for precise determination of future loads on the structure and optimizes costs. A project timeline is then established.

Technical Documentation of the Structure

The next step is to develop detailed technical documentation for the structure based on design standards, which includes:

- Static Calculations – ensuring the safety and stability of the structure.

- Technical Drawings – illustrating all elements of the structure.

- Material Specifications – defining what building materials will be used, e.g., type of structural steel and how it will be protected against corrosion.

Technical documentation is a crucial element of the project that serves as the basis for prefabrication and installation of steel components on-site.

Modeling and Optimization of the Steel Structure

Today, modeling and optimization of structures are performed using advanced CAD software. This allows engineers to accurately replicate the structure in digital form. The Finite Element Method (FEM) is also used in the design process, enabling the analysis of the structure’s behavior under various loads. This allows designers to simulate the effects of forces such as wind or snow and optimize the design for durability.

Selection of Materials and Connection Technologies

Another key step is selecting the appropriate materials. Structural steel is the most commonly chosen material due to its strength and resistance to various external factors. Additionally, the technology for connecting elements—such as welding, bolting, or riveting—must be tailored to the project’s characteristics and the type of steel used. Choosing the right connection methods is critical for ensuring the longevity and safety of the structure. Modern construction engineering allows us to utilize tools such as computer simulations to study the durability of the structure.

Prefabrication of Steel Elements and Roof Production

Once the design is approved, the process of prefabricating steel elements begins. The elements of the structure are produced in workshops and then transported to the construction site. Prefabrication shortens assembly time and increases precision. As a result, the design process concludes faster, and the finished components can be assembled with minimal issues.

Installation of Steel Structures

The installation of the steel structure is the last but equally important stage. At the construction site, prefabricated elements are assembled and connected according to the previous documentation. The assembly of a steel structure requires precise planning and the use of appropriate equipment, such as cranes, to lift heavy elements. Quality control at each stage of work is also essential to ensure that the assembly follows the design.

During installation, applicable design standards for steel structures, such as Eurocodes, which define safety standards, must also be adhered to.

Summary

Designing steel structures is a complex process that requires close cooperation between engineers, architects, and contractors. Each stage—from analyzing the investor’s requirements, through modeling and prefabrication, to installation—must be meticulously planned and executed according to technical guidelines. Thanks to modern technologies, such as CAD software and the Finite Element Method (FEM), designing steel structures has become more precise and efficient.

The team of specialists at Abastran offers comprehensive support at every stage of project execution. If you are looking for professional solutions in the design of steel structures, contact us to learn more.

👉 Contact us and gain access to modern solutions in the design and optimization of structures!

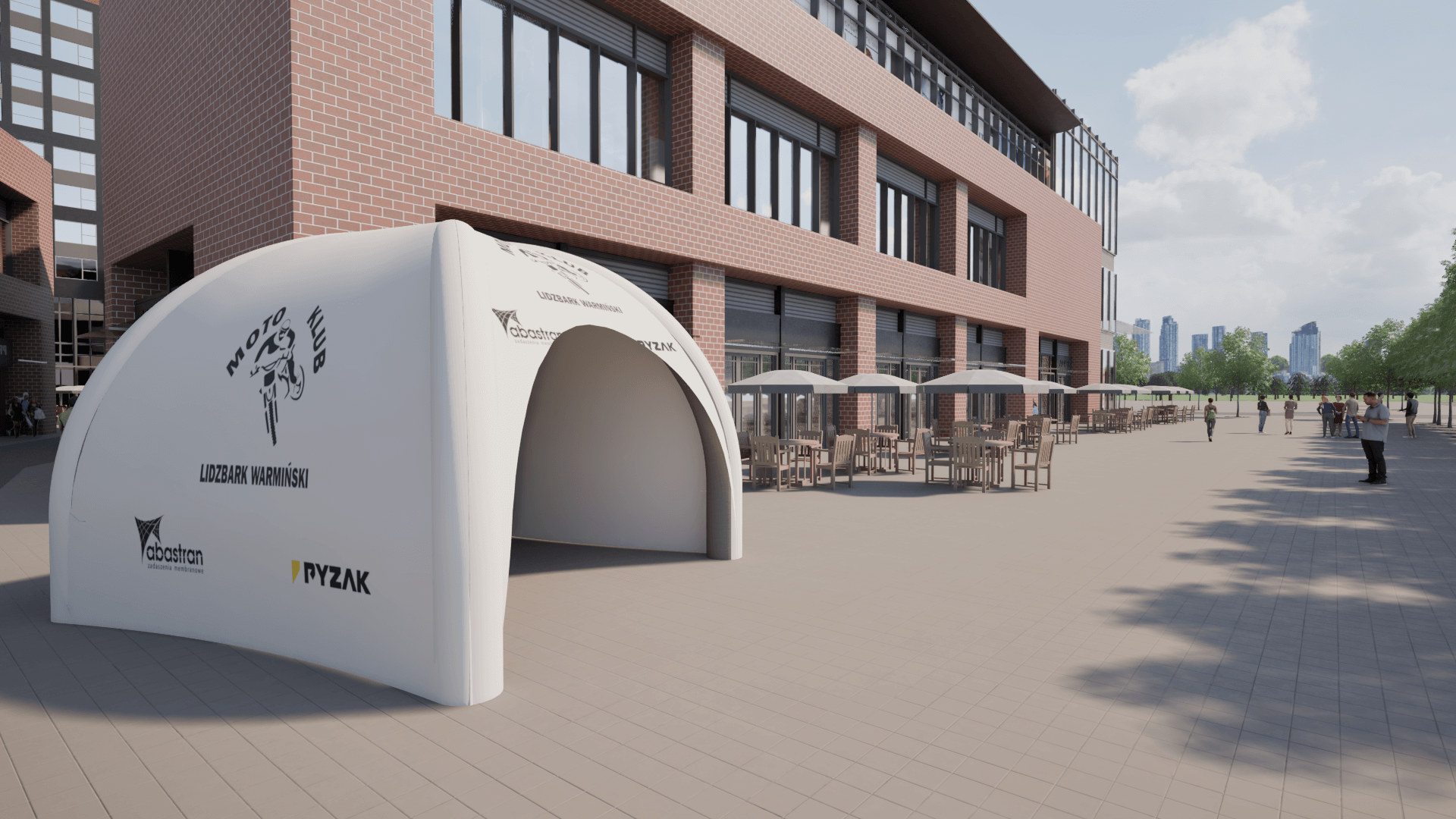

Advertising Tents as an Investment – How to Increase Brand Recognition at Events?

Competition for Innovative Membrane Roofing – Results and Inspirations

This year, we had the pleasure of organizing a competition together with the Faculty of Architecture at the Silesian University of Technology for 6th-semester students to design innovative membrane roofing. The award ceremony, held at the Faculty of Architecture in Gliwice, was the culmination of the young designers’ creative and technical journey.