Comparison of Construction Costs: Steel Halls vs. Traditional Buildings

Choosing between a steel hall and a traditional production or warehouse building is a decision that impacts construction costs, project completion time, and future operating expenses. In this article, we will compare various aspects of these two solutions.

Material Costs

Comparison of Material Costs

Steel, especially in the context of lightweight steel structures, is more expensive at the purchasing stage, but its strength and lightness can reduce construction costs. On the other hand, traditional materials like concrete and brick require more complex foundations, which can increase costs.

Lightweight Steel Structures vs. Traditional Materials

Lightweight steel structures allow for faster assembly and lower transportation costs. The use of steel hall construction translates to time and cost savings compared to traditional building methods.

Design Costs

Steel Structure Designs

Steel structure designs are more flexible and easier to modify compared to traditional building designs. The design of a steel structure often includes precise calculations that allow for better material utilization.

Membrane Architecture and Roofing

Modern technologies, such as high-quality membrane roofing, can be an integral part of steel designs, offering additional adaptive possibilities, including high resistance to various weather conditions.

Construction Costs

Assembly of Steel Structures

The assembly of steel structures, including steel halls, is generally faster and more economical compared to traditional methods. The production of steel structures and the prefabrication of components shorten construction time.

Traditional Construction Methods

Traditional production and warehouse buildings require a longer construction period, which increases labor and material costs. Additionally, assembling traditional halls often requires higher financial investments.

Operation and Maintenance

Durability of Steel Structures

Steel structures are more durable and resistant to damage, which translates to lower operating costs. Steel structure manufacturers ensure high material quality, minimizing the need for frequent repairs.

Maintenance of Traditional Buildings

Traditionally built structures may require more frequent maintenance, increasing their total operating cost. Moisture, mold, and other factors can affect the durability of the structure.

Project Completion Speed

Assembly of Steel Halls

The speed of completing a steel structure project is one of the key factors in favor of choosing this technology. Prefabricated elements are quickly assembled on-site, allowing for earlier commencement of operations. If time is of the essence, it is worth consulting a steel hall manufacturer who can create a professional steel structure design tailored to the client’s needs and design, execute, and install membrane roofing.

Construction of Traditional Buildings

Building using traditional methods is much more time-consuming, which can delay the building’s availability. Higher costs associated with prolonged construction also mean increased project management expenses.

Space Adaptation

Steel Structures and Design Flexibility

The construction of a steel hall allows for easy space adaptation to changing needs. The ability to make quick modifications to the structure is an advantage that companies in rapidly developing industries will appreciate.

Membrane Roofing and Other Adaptive Options

The use of membrane roofing, such as membrane coverings for parking lots or terraces, allows for additional use of space. Membrane structures offer lightness and a modern appearance, as well as the ability to be tailored to individual needs.

Environmental Aspects

Steel Recycling and Membrane Roofing

Metal structures made of steel are fully recyclable, making them an eco-friendly choice. Membrane roofing, including ETFE structures, also aligns with the trend of sustainable construction, offering energy-efficient and durable solutions.

Conclusion

The decision to choose a steel hall or a traditional production or warehouse building depends on many factors. Steel structures offer flexibility, durability, and lower operating costs. With fast assembly, prefabrication, and adaptive possibilities, steel halls are often a more cost-effective solution. By choosing steel, investors can count on long-lasting and eco-friendly facilities that easily adapt to changing needs.

Explore our innovative solutions in membrane and steel structures. Contact us to discuss your project and discover how we can help bring your ideas to life.

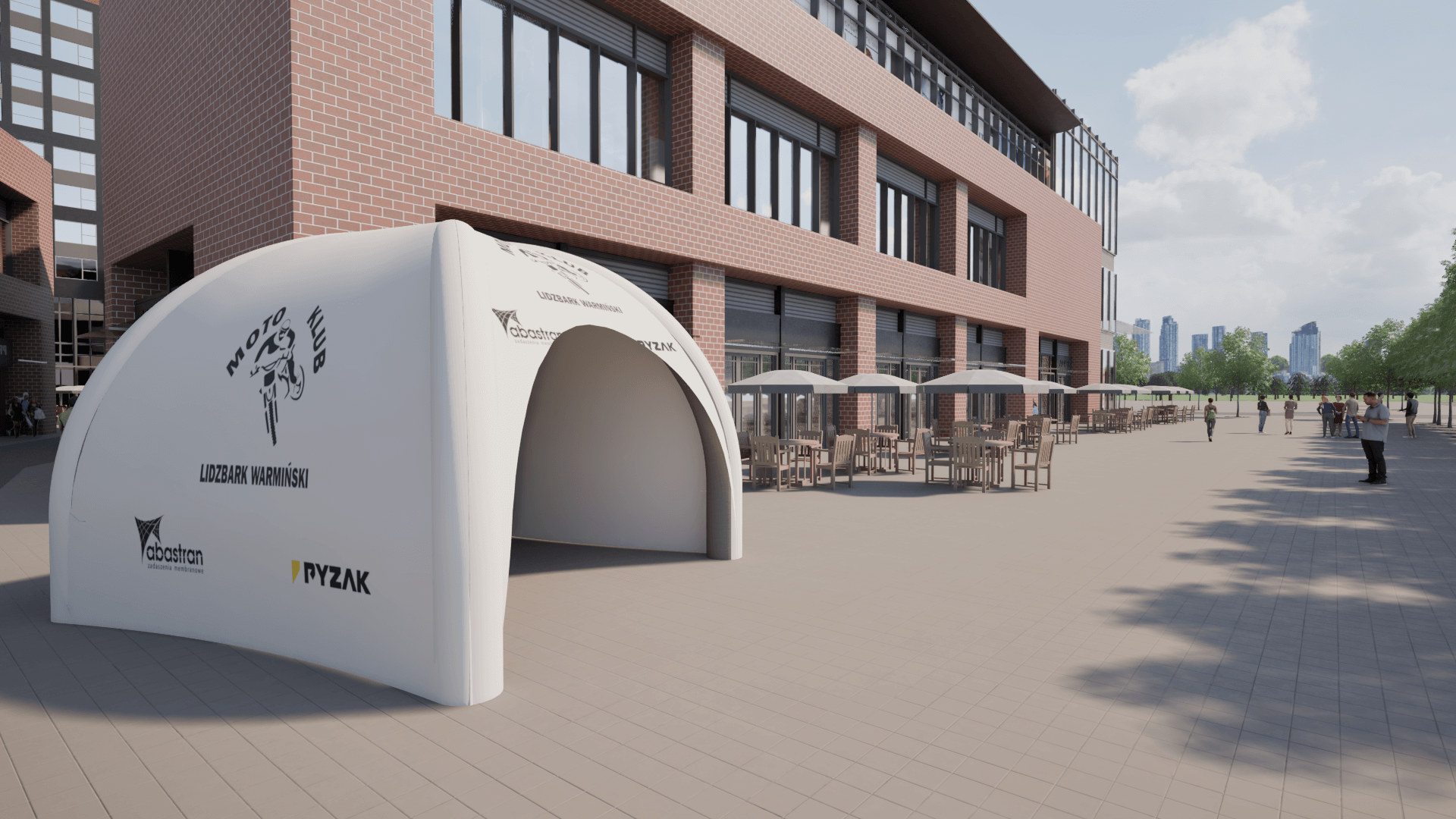

Advertising Tents as an Investment – How to Increase Brand Recognition at Events?

Competition for Innovative Membrane Roofing – Results and Inspirations

This year, we had the pleasure of organizing a competition together with the Faculty of Architecture at the Silesian University of Technology for 6th-semester students to design innovative membrane roofing. The award ceremony, held at the Faculty of Architecture in Gliwice, was the culmination of the young designers’ creative and technical journey.